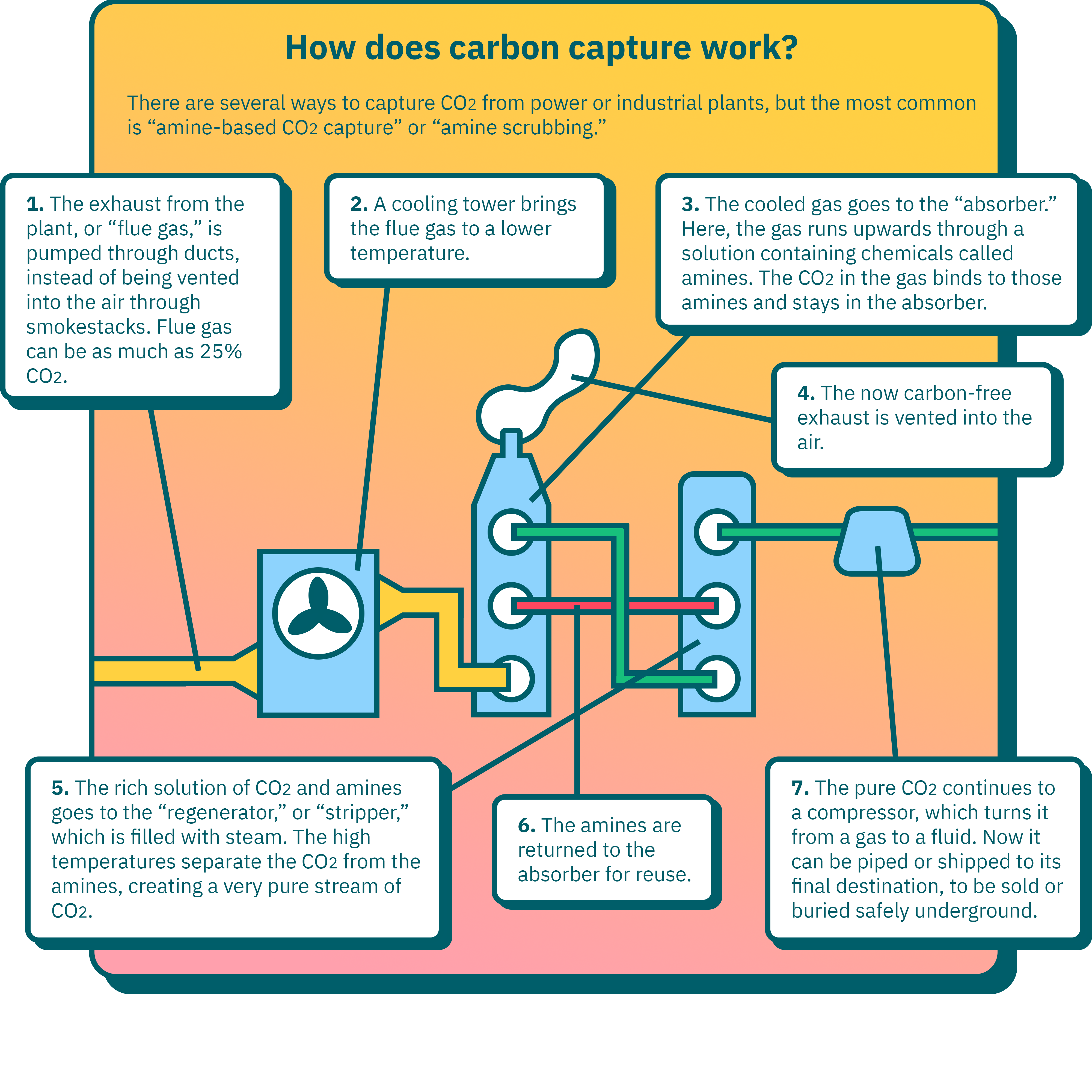

To date, however, their use in PC power plants has been restricted to slipstream applications, and no definitive analysis exists as to the actual costs for a full-scale capture plant. These types of processes have been developed and deployed commercially in the refinery and chemical industries. Compressing it from atmospheric to pipeline pressure (about 2,000 psia) will incur a large auxiliary power load on the overall power plant system.Ī post-combustion CO 2 capture absorption process based on chemical solvents such as amines is pictorially shown below. Trace impurities (e.g., particulate matter, sulfur dioxide, nitrogen oxides in the flue gas can degrade sorbents and reduce the effectiveness of certain CO 2 capture processes.CO 2 is present at dilute concentration (typically 13 to 15 volume percent for PC power plants and 3 to 4 percent for natural gas-fired plants) and at low pressure (slightly above atmospheric) thus, a large volume of gas has to be treated.Separating CO2 from this flue gas stream is challenging for several reasons: The boiler exhaust, or flue gas, consists mostly of nitrogen (N2), and CO2. In a typical PC power plant, fuel is burned with air in a boiler to produce steam, which drives a turbine to generate electricity. Post-combustion CO 2 capture is primarily applicable to conventional natural gas and pulverized coal-fired (PC) power generation. More detailed discussion on the post-combustion, pre-combustion, and oxy-combustion technologies for CO 2 capture follows. The following figure illustrates those capture approaches, noting challenges, as well as established and developmental technologies in those areas. Interagency Working Group Initial ReportĬarbon dioxide (CO 2) capture systems may be classified into three categories: post-combustion, pre-combustion, and oxy-combustion.Summary Information for Extramural R&D Awards.FECM Extramural R&D Final Technical Reports.Solicitations and Funding Opportunities.Center for Sustainable Fuels and Chemicals (CSFC).Science-based Artificial Intelligence and Machine Learning Institute (SAMI).Advanced Alloys Signature Center (AASC).Strategic Systems Analysis and Engineering.Materials Engineering and Manufacturing.Cybersecurity, Energy Security, and Emergency Response.Office of Energy Efficiency and Renewable Energy.Historically Black Colleges and Universities and Minority Serving Institutions Program.

0 kommentar(er)

0 kommentar(er)